In the bustling world of construction, a stationary hydraulic dump trailer is as useful as a chocolate teapot. This prevalent issue, where the trailer stubbornly refuses to lower, can bring operations to a grinding halt.

This article aims to explore eight practical approaches to tackle this problem, ranging from purging air in the system to replacing a faulty check valve. With this knowledge, one can not only troubleshoot these stubborn machines but also potentially prevent such situations.

Curious to learn more? Let's delve into the nitty-gritty of keeping your hydraulic dump trailer in tip-top shape.

Key Takeaways

- Regularly check and maintain hydraulic fluid levels to prevent the pump from running dry.

- Inspect and replace any faulty components like check valves, hydraulic pump, and worn-out packing.

- Ensure all connections are secure and use an ohmmeter to test the wiring for any issues.

- Follow a robust maintenance routine and inspect the trailer for possible damage, including the hydraulics, wiring, fuse, and solenoid.

Purging Air From the System

How do you purge air from the hydraulic system of your dump trailer? It's not as intimidating as it sounds. Let's navigate through the proper air removal techniques.

To start, locate the bleeder valve. This little component is key to your liberation from trapped air. Now, let's troubleshoot. Is the valve functioning as it should? If it's not, that's an issue needing immediate attention. But assuming it's in good shape, open the valve. This allows the entrapped air to escape, which is important for smooth hydraulic fluid flow.

Once the air's purged, close the valve securely. Remember, it's not just about the mechanics, but also the art of keen observation and detailed analysis. With these steps, you've mastered the air purge process, freeing your hydraulic system of unwelcome air.

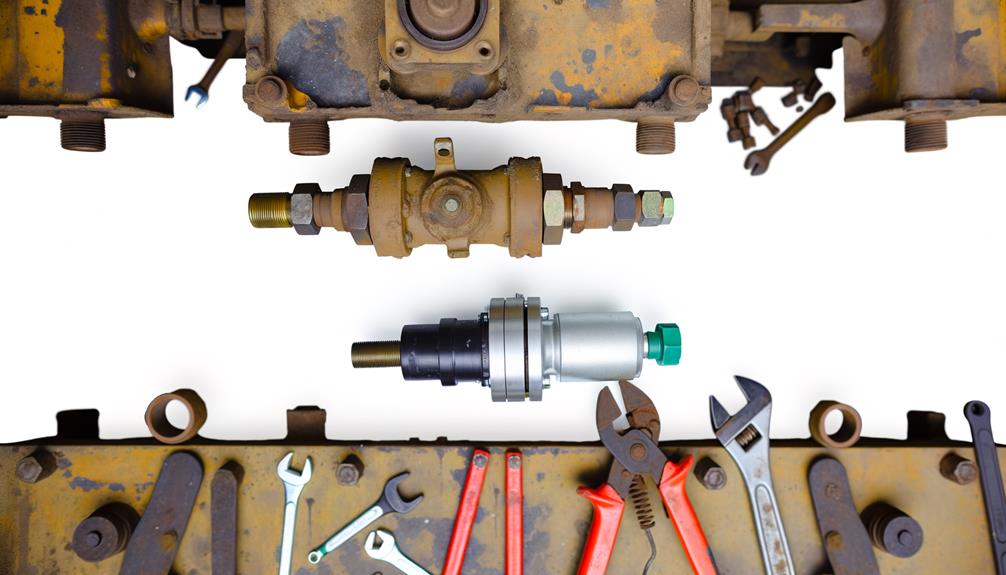

Replacing a Faulty Check Valve

When dealing with a disrupted fluid flow in your hydraulic dump trailer, one common culprit to ponder is a faulty check valve. Check valve troubleshooting typically reveals common issues like valve stickiness or a failure to close properly, which could obstruct fluid movement in your hydraulic system.

To rectify this, valve replacement steps are necessary. Start by disconnecting the hydraulic system. Next, carefully remove the faulty check valve. Replace it with a new, functional one, ensuring correct placement and orientation. Reconnect the hydraulic system and test the new valve's functionality. This should restore peak fluid flow.

If problems persist, further hydraulic system troubleshooting may be required. Assiduously replacing a faulty check valve can often liberate your hydraulic dump trailer from its stagnant state.

Addressing Worn Out Packing

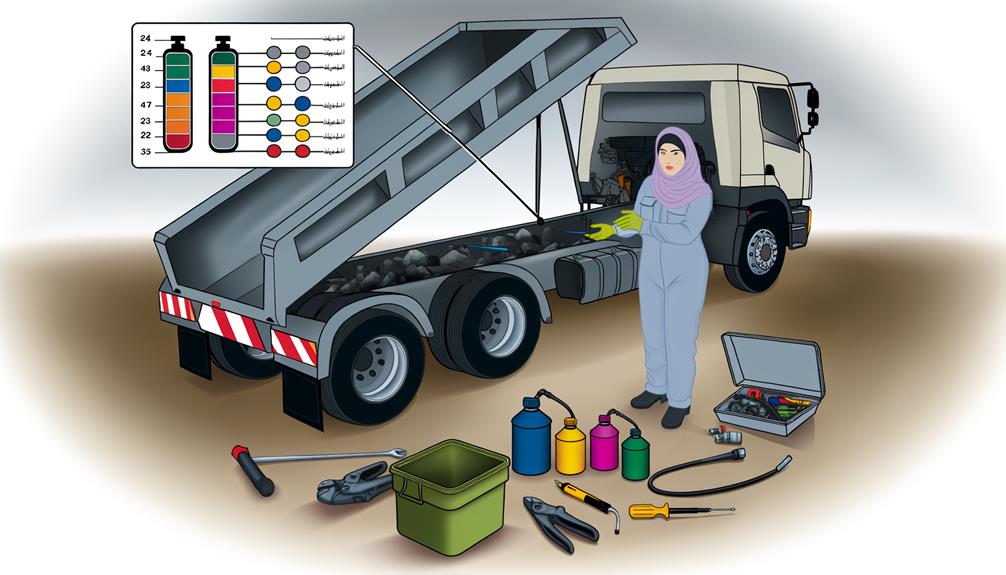

While a faulty check valve can disrupt fluid flow, another common issue in the hydraulic dump trailer is the deterioration of packing. Over time, packing can wear out and compromise the sealing solutions, leading to hydraulic fluid leaks.

Here are four steps to address worn-out packing:

- Identify the Issue: Check for signs of wear or damage in the packing. Visible leaks or reduced hydraulic pressure can indicate worn-out packing.

- Remove the Old Packing: Use appropriate packing removal techniques to avoid causing further damage to the system.

- Install New Packing: Carefully install the new packing, making sure it fits snuggly to create a tight seal.

- Test the System: After replacing the packing, test the hydraulic system to make sure there are no more leaks and the trailer functions properly.

Maintaining Hydraulic Fluid Levels

In the domain of hydraulic dump trailer maintenance, ensuring the proper level of hydraulic fluid is a critical step that should never be overlooked. Maintaining fluid levels prevents corrosion and aids in monitoring leaks, thereby guaranteeing the trailer's smooth operation. Regular inspection is necessary to notice any sudden drops in fluid levels, which may indicate a leak.

| Maintenance Steps | Purpose | Impact |

|---|---|---|

| Check fluid levels regularly | To detect leaks early | Reduces risk of major faults |

| Top off hydraulic fluid | To maintain the best fluid level | Ensures smooth operation |

| Prevent corrosion | To maintain fluid quality | Prolongs equipment lifespan |

In the domain of hydraulic dump trailer maintenance, maintaining hydraulic fluid levels is an ongoing task that requires vigilance and commitment. It's not just about keeping the trailer running. It's about liberating the equipment from potential constraints to its performance.

Inspecting and Repairing Connections

How secure are the connections in your hydraulic dump trailer system? Inspecting and repairing connections is critical to guarantee peak operation.

- Testing electrical connections: Use a multimeter to assess the conductivity of the circuit. Any inconsistency can indicate a faulty connection needing immediate attention.

- Inspecting for physical damage: Look for any signs of wear or breakage. Damaged connections can cause hydraulic fluid leaks or electrical disruptions.

- Preventing corrosion: Regularly clean and apply anti-corrosion spray to the connections. Corrosion can impair electrical flow and cause system failure.

- Tightening loose connections: Loose connections can disrupt fluid or electrical flow. Ensure all fittings are tight and secure.

Frequently Asked Questions

What Are the Signs of a Faulty Hydraulic Pump in a Dump Trailer?

Signs of a faulty hydraulic pump include disrupted fluid flow and a non-functional dump trailer. Pump replacement is key in operation troubleshooting. Proper installation of the new pump is crucial for efficient performance.

How Can Regular Maintenance Prevent Hydraulic Dump Trailer Issues?

Regular maintenance, like adhering to a strict schedule and implementing preventive measures, can help avoid hydraulic dump trailer issues. It guarantees parts' peak performance, reduces wear, and promptly identifies potential problems before they escalate.

What Steps Should Be Taken if Visible Damage Is Found on the Trailer or Its Hydraulics?

Upon identifying visible damage, they must conduct a thorough damage assessment. Then, they'll explore repair options, either fixing it themselves or seeking professional help. It's crucial they resolve issues promptly to prevent further complications.

How Often Should the Hydraulic Fluid Levels Be Checked and Topped Off?

To maintain peak performance, one should regularly check hydraulic fluid levels. Ideally, they'd do this every use, or at least weekly. Leak detection and proper fluid disposal are essential parts of this routine maintenance.

What Common Problems Could Arise From a Lack of Proper Maintenance of a Hydraulic Dump Trailer?

Neglecting maintenance can lead to issues like air in the system, faulty valves, worn-out packing, or a malfunctioning pump. Adhering to a maintenance schedule and employing preventive techniques can prevent these common problems.

Conclusion

To summarize, troubleshooting a hydraulic dump trailer that won't descend involves several steps.

Purging air from the system,

replacing faulty check valves,

addressing worn-out packing, and

maintaining ideal hydraulic fluid levels are critical.

Regular inspection and repair of connections can prevent sudden breakdowns.

Understanding these approaches offers a complete solution to the problem, potentially saving time, money, and frustration.

Regular maintenance is a must for smooth and efficient operation.