When you’re searching for hydraulic systems for dump trailers, you’re looking for the heart that powers the lifting and tipping mechanism essential for your operations. These systems are a blend of components such as pumps, cylinders, and hydraulic fluid that work together to move your heavy loads with ease.

Whether you’re a small to medium-sized business owner in construction, landscaping, or any industry requiring heavy lifting and material transport, understanding these systems can significantly impact your efficiency and safety. A well-chosen hydraulic system ensures your dump trailer operates smoothly, helping you tackle projects with confidence.

Quick Snapshot:

– Types: Gear Pumps, 12 Volt Hydraulic Pumps, Double Acting Hydraulic Pumps

– Key Considerations: Size, Pressure Rating, Flow Rate, Compatibility, Reservoir Volume

– Maintenance: Regular Fluid Replacement, Leak Detection, Pressure Checks

For small to medium-sized business owners, navigating the selection, maintenance, and troubleshooting of hydraulic systems can be daunting. This guide aims to simplify these aspects, offering insights into choosing the right system, ensuring it fits your specific operational needs, and how to keep it running at its best.

Each section of this article is designed to break down complex information into accessible, actionable advice. From maintenance tips to help you avoid common pitfalls to a deep dive into different types of hydraulic pumps, we’ve got you covered. Let’s explore how to empower your operations with the right hydraulic systems for your dump trailers.

Understanding Hydraulic Systems for Dump Trailers

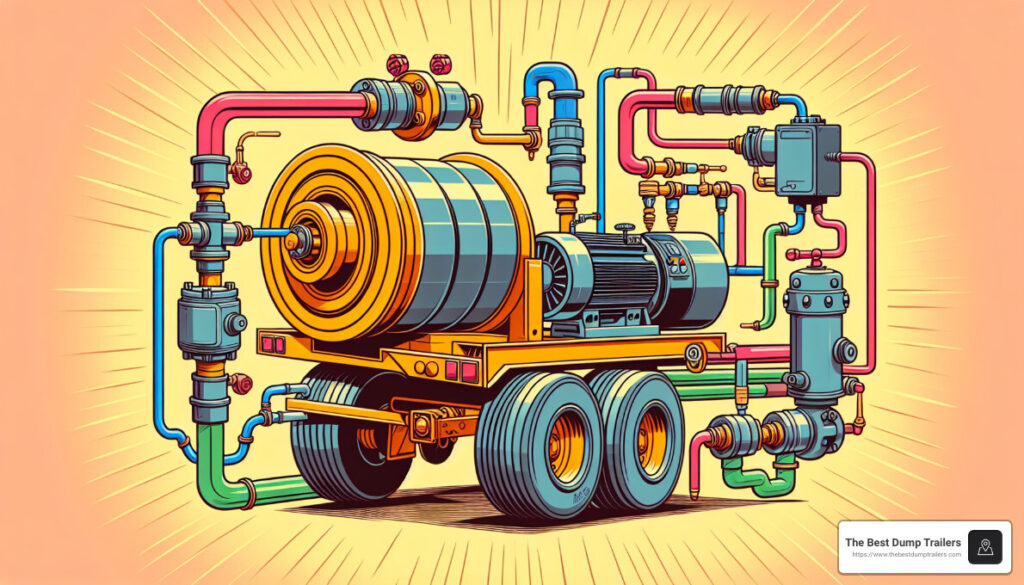

When it comes to dump trailers, the heart of their functionality lies within the hydraulic system. This system is what allows the trailer to lift, tilt, and lower the load with ease. But how does it work? Let’s break it down into simple terms.

Hydraulic Principles

At its core, a hydraulic system operates on a basic principle: when you apply force at one point, it is transmitted to another point using an incompressible fluid, usually hydraulic fluid. This process allows for the multiplication of forces, making it easier to lift heavy loads with minimal effort.

Components

A typical hydraulic system for a dump trailer consists of several key components:

- Hydraulic Pump: This is the heart of the system. It converts mechanical energy into hydraulic energy by moving hydraulic fluid from the reservoir into the system.

- Hydraulic Cylinders: These are the muscles. They use the hydraulic energy to create motion and force to lift or lower the trailer.

- Reservoir: This is where the hydraulic fluid is stored. It’s like the fuel tank for your hydraulic system.

- Valves: These control the flow and direction of the hydraulic fluid, allowing the operator to control the movement of the dump trailer.

- Hoses and Fittings: These are the veins and arteries, carrying hydraulic fluid to and from different parts of the system.

Hydraulic Fluid

The hydraulic fluid is more than just a medium for transferring energy. It also lubricates the system, helping to reduce friction and wear on the components. Additionally, it serves as a coolant, helping to keep the system at an optimal temperature during operation.

Choosing the right hydraulic fluid is crucial. It must have the appropriate viscosity for the temperature range in which the equipment will operate. Moreover, using the wrong type of fluid can lead to damage and reduced efficiency of the system.

In Summary

Understanding the basics of hydraulic systems for dump trailers is essential for anyone looking to utilize this powerful tool effectively. By grasping the principles, components, and the role of hydraulic fluid, operators can ensure their dump trailers perform optimally, leading to increased productivity and longevity of the equipment.

Maintaining your hydraulic system, including regular fluid checks and component inspections, is key to avoiding downtime and costly repairs. With this knowledge, you’re well-equipped to make the most of your dump trailer’s capabilities, ensuring smooth and efficient operations for your business.

In the next section, we’ll dive into the different types of hydraulic pumps available for dump trailers and how to select the right one for your needs.

Types of Hydraulic Pumps for Dump Trailers

When it comes to powering your dump trailer, the heart of the hydraulic system is the pump. It’s what moves the hydraulic fluid around, creating the pressure needed to lift, hold, and lower your trailer’s bed. Let’s break down the three main types of hydraulic pumps you’ll encounter: Gear Pumps, 12 Volt Hydraulic Pumps, and Double Acting Hydraulic Pumps.

Gear Pumps

Gear Pumps are a popular choice due to their simplicity and durability. They work by meshing gears together to pump fluid through the system. Here’s why they’re great for dump trailers:

- Reliability: With fewer moving parts, gear pumps are less likely to break down.

- Efficiency: They provide a steady flow of hydraulic fluid, making your dump trailer’s lifting mechanism smooth.

- Cost-effective: Generally, gear pumps are more affordable than other types.

12 Volt Hydraulic Pump

12 Volt Hydraulic Pumps are designed for mobile applications like dump trailers. They’re powered by the trailer’s electrical system, making them convenient for on-the-go operations. Key benefits include:

- Portability: Their compact size makes them easy to install in various locations on your trailer.

- Ease of Use: Many models come with remote controls, allowing you to operate your dump trailer from a distance.

- Power Efficiency: They’re designed to provide enough power for lifting without draining your trailer’s battery too quickly.

Double Acting Hydraulic Pump

Double Acting Hydraulic Pumps are a bit more complex. They can push hydraulic fluid in both directions, allowing for more control over the lifting and lowering processes. Here’s why they stand out:

- Versatility: They can be used in applications requiring more precise control over movement, such as adjustable dumping speeds.

- Power: These pumps offer robust performance for heavier loads, making them suitable for larger dump trailers.

- Control: With the ability to manage both lifting and lowering, you can prevent sudden drops, adding an extra layer of safety to your operations.

Choosing the Right Pump for Your Dump Trailer

Selecting the right hydraulic pump involves considering your dump trailer’s size, the weight of the loads you’ll be carrying, and the level of control you need over the lifting and lowering processes. Here are a few tips:

- Assess Your Needs: Think about the most demanding tasks you’ll perform with your dump trailer and choose a pump that can handle those requirements.

- Compatibility: Ensure the pump you select is compatible with your trailer’s hydraulic system and electrical setup.

- Budget: While it’s tempting to go for the cheapest option, the pump is the heart of your hydraulic system. Investing in a high-quality pump can save you money on maintenance and repairs in the long run.

By understanding the types of hydraulic pumps available and considering your specific needs, you can select the right pump to power your dump trailer efficiently. In the next section, we’ll explore hydraulic hoist systems, another crucial component for maximizing the performance of your dump trailer. Stay tuned for insights on selecting the best hoist system for your operations!

Selecting the Right Hydraulic Pump

Selecting the right hydraulic pump for your dump trailer is like picking the perfect engine for your car. It’s all about finding the balance between power, efficiency, and compatibility. Let’s dive into the key factors you need to consider:

Size

Think of the size of the hydraulic pump as you would the size of a shoe. Too small, and it won’t be able to handle the load. Too big, and you’ll be wasting power (and money). The size of the pump should match the requirements of your dump trailer’s hydraulic system to ensure efficient operation.

Pressure Rating

The pressure rating is akin to the horsepower of your car. It’s all about how much power the pump can handle. Ensure the pump’s pressure rating meets or exceeds the needs of your dump trailer. This will prevent hydraulic system damage and ensure smooth operation under load.

Flow Rate

Flow rate is the speed at which hydraulic fluid moves through the system, similar to the speed of your car. A pump with an adequate flow rate will operate the dump bed effectively, ensuring a smooth and timely lifting and lowering process. Too slow, and you’ll be waiting forever. Too fast, and you might compromise control.

Compatibility

Imagine trying to run a diesel engine on gasoline. Compatibility is crucial. The voltage of the hydraulic pump should align with the power source of your trailer to avoid operational hiccups. Also, consider the hydraulic fluid type recommended for the pump to ensure longevity and peak performance.

Reservoir Volume

The reservoir volume is like the fuel tank of your car. It determines how much hydraulic fluid the system can hold. A larger reservoir might be necessary for larger operations to reduce downtime due to refilling. However, balance size with space requirements on your trailer.

When selecting a hydraulic pump, it’s not just about the individual components but how they work together to power your dump trailer efficiently. Take the time to assess your needs, considering the load size, frequency of use, and operational conditions. A well-chosen pump will save you time and money in the long run by optimizing performance and minimizing maintenance issues.

The right hydraulic pump is the heart of your dump trailer’s hydraulic system, pumping life into your operations. By carefully considering size, pressure rating, flow rate, compatibility, and reservoir volume, you can ensure your dump trailer operates smoothly and efficiently, ready to tackle any job that comes your way.

In the next section, we’ll explore hydraulic hoist systems, another crucial component for maximizing the performance of your dump trailer. Stay tuned for insights on selecting the best hoist system for your operations!

Hydraulic Hoist Systems for Dump Trailers

When it comes to lifting heavy loads with precision and ease, the hydraulic hoist system in your dump trailer plays a pivotal role. Let’s dive into the different types of hoist systems, focusing on scissor hoists, direct push kits, and understanding cylinder sizes.

Scissor Hoist

A Scissor Hoist is named for its mechanism that resembles a pair of scissors. These are incredibly efficient for dump trailers, providing stability and power. The 10 Ton Hydraulic Scissor Hoist Kit (PH520) is a prime example, suitable for 10′ – 16′ dump beds. It’s designed to lift heavy loads vertically with a compact mechanism that expands as it lifts. This type of hoist is ideal for dump trailers used in construction and landscaping, where stability and lifting power are paramount.

Direct Push Kits

Direct Push Kits, like the Dump Trailer Hydraulic Cylinder Direct Push Kit – PCK 3530-2DP, offer a straightforward approach to lifting. These kits use a hydraulic cylinder to push the dump bed up and down. Unlike the scissor hoist, the direct push method applies force directly, providing a powerful lift even in tight spaces. This kit includes a double-acting hydraulic pump and all necessary fittings, making it a comprehensive solution for those needing a robust lifting mechanism.

Cylinder Sizes

The size of the hydraulic cylinder is crucial for the lifting capacity and efficiency of your dump trailer. For example, the 3.5 x 30 Cylinder Assembly in the PCK 3530-2DP kit is designed for medium to heavy-duty applications, offering a balance between size and power. In contrast, the PCK 530 kit comes with a larger 5 x 30 Cylinder Assembly, suitable for even heavier loads. Selecting the right cylinder size is essential for ensuring that your dump trailer can handle the intended payload without overburdening the hydraulic system.

Selecting the Right Hoist System

When choosing a hydraulic hoist system for your dump trailer, consider the following:

- Load Capacity: Ensure the system can handle the maximum load you plan to transport.

- Dump Bed Size: Match the hoist system to the size of your dump bed for optimal performance.

- Usage Frequency: For frequent, heavy use, invest in a robust system like a direct push kit with a larger cylinder.

- Installation and Maintenance: Consider ease of installation and the availability of replacement parts.

Real-World Application

A landscaping business owner, for example, might opt for a Scissor Hoist for its stability when hauling uneven loads like rocks or soil. In contrast, a construction company dealing with heavier, more uniform loads might benefit from the direct lifting power of a Direct Push Kit.

Conclusion

Selecting the appropriate hydraulic hoist system for your dump trailer is critical for safe, efficient operations. Whether you choose a scissor hoist for its stability and compact design or a direct push kit for its straightforward power, ensuring it matches your dump trailer’s size and your business’s needs will keep your operations running smoothly.

In the next section, we’ll cover maintenance and troubleshooting for these hydraulic systems, ensuring you’re equipped to keep your dump trailer in top condition.

Maintenance and Troubleshooting

Keeping your dump trailer’s hydraulic system in peak condition is crucial for smooth operations. Let’s dive into the essentials of maintenance and how to troubleshoot common issues.

Fluid Replacement:

Just like changing the oil in your car, replacing the hydraulic fluid in your dump trailer is key to its longevity and performance. Aim to change the fluid at least once a year. Using the right type of hydraulic fluid is also critical. Check your manufacturer’s recommendations to ensure compatibility.

Leak Detection:

Leaks can be a major problem in hydraulic systems, leading to loss of pressure and potential damage. Regularly inspect hoses, fittings, and seals for signs of wear or damage. A small leak can quickly turn into a big problem if not addressed promptly.

Pressure Checks:

Keeping an eye on the hydraulic system’s pressure is vital. Use a pressure gauge to monitor the system’s performance. If you notice fluctuations or drops in pressure, it could indicate a leak or a problem with the pump.

Troubleshooting Common Issues:

1. Hydraulic Pump Failure: If your dump trailer’s hydraulic pump isn’t working as expected, first check the electrical connections and fuse. A blown fuse or loose wire can often be the culprit.

2. Slow Operation: If the hydraulic system seems sluggish, it could be due to low fluid levels, air in the system, or a clogged filter. Make sure the fluid is topped up, bleed any air from the system, and replace the filter if necessary.

3. Hydraulic Cylinder Issues: Problems with the hydraulic cylinder can manifest as leaks or a failure to lift. Inspect the cylinder for any visible damage and ensure all seals are intact.

Regular maintenance not only prevents downtime but also extends the life of your dump trailer’s hydraulic system. Here’s a quick checklist for keeping things running smoothly:

– Weekly: Check for leaks and inspect hoses and fittings.

– Monthly: Test the hydraulic fluid level and quality.

– Annually: Replace the hydraulic fluid and inspect the pump and cylinder for wear.

By staying on top of these maintenance tasks and knowing how to troubleshoot common issues, you can ensure your hydraulic system for dump trailer remains reliable and efficient. This proactive approach saves time and money, keeping your business moving forward without unexpected interruptions.

In the next section, we’ll answer some frequently asked questions about hydraulic systems for dump trailers, providing you with even more insights to optimize your operations.

Frequently Asked Questions about Hydraulic Systems for Dump Trailers

How does the hydraulic system work on a dump trailer?

A hydraulic system for a dump trailer uses fluid power to perform work. Here’s a simple breakdown:

- Power Source: The hydraulic pump, which is the heart of the system, is powered by the trailer’s battery or a separate power unit.

- Fluid Movement: When activated, the pump moves hydraulic fluid from the reservoir through hoses to the cylinder(s).

- Lifting Action: The fluid’s pressure increases in the cylinder, pushing the piston and causing the trailer bed to lift.

- Control: You control the lifting and lowering action with a remote or a switch, managing the flow of the fluid.

This system allows for heavy loads to be lifted with less physical effort, making dump trailers incredibly efficient for hauling and unloading materials.

How to choose a hydraulic pump for a dump trailer?

Choosing the right hydraulic pump involves several factors:

- Size and Weight of Loads: Consider the maximum weight you plan to haul. This determines the pump’s required pressure and flow rate.

- Voltage Compatibility: Ensure the pump’s voltage matches your trailer’s power source.

- Reservoir Volume: Larger loads require a pump with a larger fluid reservoir to maintain adequate pressure over multiple cycles.

- Pump Type: Decide between a single or double-acting pump based on whether you need control over both lifting and lowering actions.

- Material and Durability: Pumps come with steel or plastic reservoirs. Steel is more durable but heavier and typically more expensive.

Matching these factors with your specific needs ensures that your hydraulic system enhances your dump trailer’s efficiency and longevity.

What type of lift is best for a dump trailer?

The best type of lift for your dump trailer depends on your specific needs:

- Scissor Hoist: Offers high lifting capacity and stability, ideal for heavy loads. It’s best for larger dump trailers needing to haul dense materials like dirt, gravel, or construction debris.

- Direct Push Kits: These use hydraulic cylinders directly pushing the bed up. They’re simpler and can be more compact but might offer less lifting power compared to scissor hoists.

- Telescopic Cylinders: Best for very heavy-duty or commercial applications where vertical space is limited. They provide the greatest lifting force but are more complex and expensive.

Consider the types of materials, the volume and weight you plan to haul, and your trailer’s size when choosing the lift type. Each has its advantages, and the right choice ensures efficient operation tailored to your hauling needs.

Maintaining your hydraulic system for dump trailer is crucial for safe and efficient operations. Regular checks and understanding how to troubleshoot common issues can save you time and money, keeping your business on track.

Conclusion

Navigating hydraulic systems for dump trailers can be complex, but armed with the right information, it becomes a manageable and even empowering aspect of your business’s operations. From understanding the basic principles of hydraulics to selecting the perfect pump and maintaining your system in peak condition, every step is crucial in ensuring your dump trailer serves you reliably and efficiently.

At TheBestDumpTrailers.com, we’re committed to not just providing you with high-quality dump trailers but also ensuring you have the knowledge and resources to maintain them. Whether you’re a small business owner in the construction and landscaping sector or a heavy equipment enthusiast, our goal is to help you navigate the challenges and opportunities that come with managing and maintaining heavy equipment.

Remember, a well-maintained hydraulic system for your dump trailer is not just about avoiding downtime; it’s about maximizing efficiency, safety, and the longevity of your equipment. Regular maintenance, including fluid replacement, leak detection, and pressure checks, is essential. And when issues arise, knowing how to troubleshoot common problems can make all the difference.

In conclusion, whether you’re exploring the latest in hydraulic hoist systems, selecting a hydraulic pump that matches your needs, or seeking advice on maintenance and troubleshooting, we’re here to support you every step of the way. The world of dump trailers is evolving, with technological advancements and innovative solutions emerging all the time. Staying informed and prepared is key to leveraging these developments for your business’s benefit.

Thank you for joining us on this journey through the intricacies of hydraulic systems for dump trailers. We hope this guide has illuminated the path and provided you with the valuable insights needed to make informed decisions for your operations. For more information, tips, and guidance, keep exploring TheBestDumpTrailers.com. Together, let’s tackle the challenges and seize the opportunities that lie ahead in dump trailers.