While the unassuming telescopic cylinder might not often feature in everyday conversation, it's an unsung hero in many industries. These compact yet powerful devices, with their unique ability to extend several times their retracted length, are instrumental in a variety of equipment from dump trucks to cranes.

But, did you know these cylinders are also making waves in aerospace and marine applications? Now, isn't it intriguing to explore how this underappreciated hydraulic component is pushing boundaries in such diverse fields?

Key Takeaways

- Telescopic cylinders offer multiple stages for extended reach in applications like dump trucks, cranes, and agricultural equipment.

- These cylinders are essential in industries like mining and aerospace for precise load handling, extended reach, and weight reduction.

- They provide compact actuation solutions, enhancing control and maneuverability in various machinery.

- Telescopic cylinders are adaptable, supporting diverse terrains and attachments in mining equipment for efficient operations.

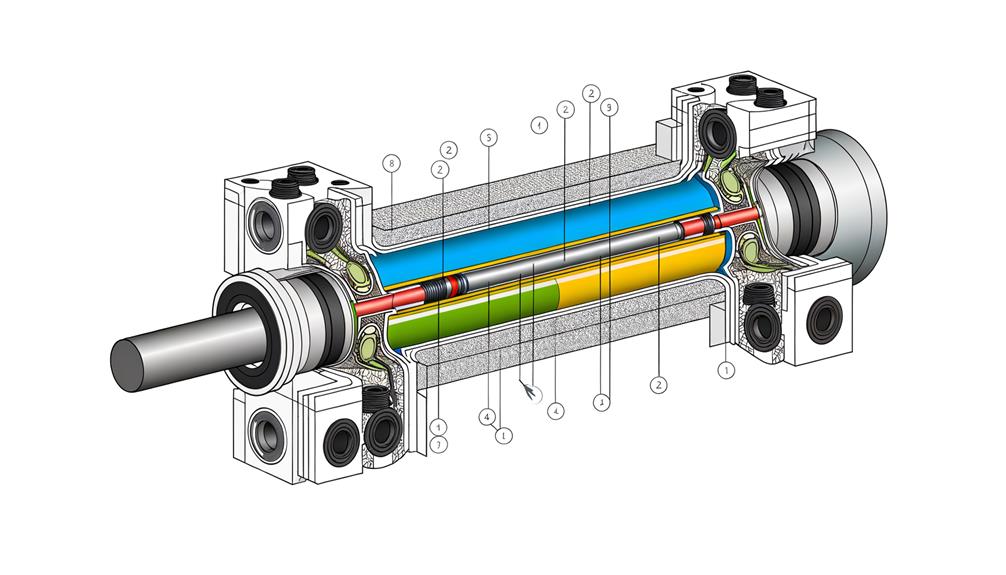

Understanding Hydraulic Cylinder Features

Delving into the technicalities, hydraulic cylinders play a pivotal role in providing surface coating for corrosion resistance with features like nickel, chrome, and ceramic plating. This ensures durability and longevity across various industrial applications.

The choice of hydraulic cylinder materials is crucial to withstand harsh industrial conditions, resist wear and tear, and maintain optimal performance. These cylinders, known for their exceptional strength and durability, are instrumental in empowering various industrial applications from manufacturing to construction and material handling to offshore structures.

They have become a critical component of industrial machinery, enabling automation and efficient operations. Hydraulic cylinders are designed to handle variations in load and pressure, following Pascal's law. They often incorporate pressure compensating valves and control mechanisms for precise operation.

Exploring Telescopic Cylinders

Diving deeper into the world of hydraulic mechanisms, we find that telescopic cylinders, with their multi-stage design, offer an extended reach while maintaining a compact retracted length, making them an ideal choice for applications such as dump trucks, cranes, and agricultural equipment. These cylinders feature innovative design concepts that allow them to adapt to different operational demands.

Their robust construction guarantees durability, while their design promotes efficiency and versatility. Performance comparisons with other hydraulic systems reveal that telescopic cylinders offer superior control and precision, making them a preferable option in various industrial settings.

As we explore these cylinders further, we discover that their unique design and performance characteristics greatly contribute to their increasing popularity in the heavy machinery industry.

Benefits of Hydraulic Cylinders

Understanding the benefits of hydraulic cylinders, it's clear they play a pivotal role in various industries due to their high power-to-size ratio, ability to handle heavy loads, and durability in demanding environments. These cylinders, due to their hydraulic efficiency improvements, offer robust and reliable solutions for tasks requiring substantial force.

- High power-to-size ratio: Thanks to advancements in cylinder material technology, they can exert huge forces while maintaining a compact size.

- Heavy load handling: The design of hydraulic cylinders enables them to handle significant weights, important in industries such as construction and manufacturing.

- Durability: Capable of withstanding harsh conditions, these cylinders offer long-lasting performance, hence reducing replacement and maintenance costs.

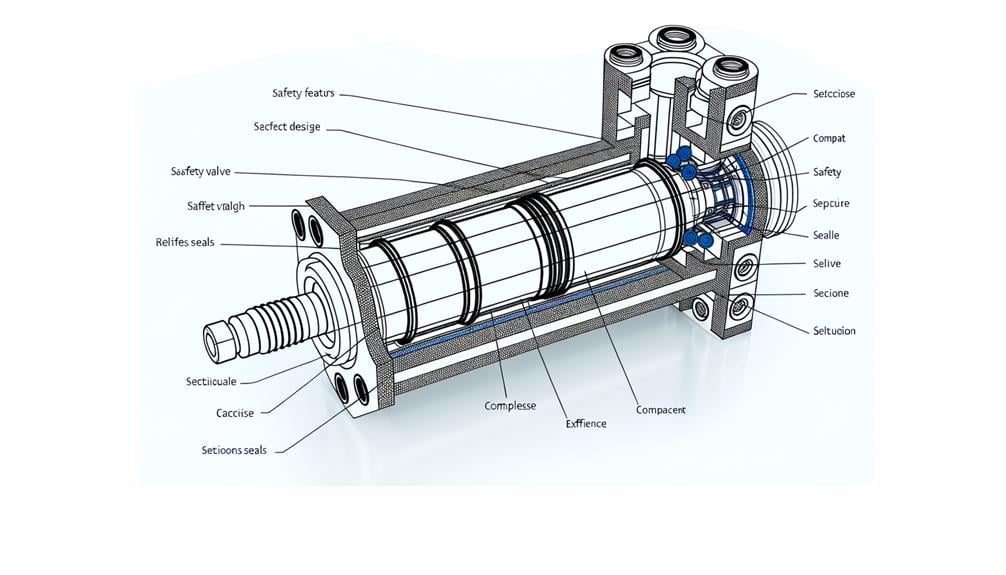

Safety and Efficiency Considerations

When operating machinery equipped with telescopic cylinders, prioritizing safety and efficiency is paramount to guarantee smooth and accident-free operations. Ensuring operator safety hinges largely on thorough safety training. This includes understanding the mechanical intricacies, load capacities, and emergency procedures associated with these cylinders. Regular inspection and maintenance also contribute greatly to safety.

On the efficiency front, telescopic cylinders offer a high power-to-size ratio, promoting energy efficiency. The incorporation of load-sensing technology can further enhance this efficiency by adjusting power consumption based on the load, hence saving energy. This means that these cylinders not only safeguard safety but also contribute to greener, more sustainable operations. This combination of safety and efficiency makes telescopic cylinders a preferred choice for demanding industrial applications.

Load Handling and Adaptability

Continuing the discussion on telescopic cylinders, it's worth noting their impressive load handling capabilities and adaptability to different terrains, which further enhance their applicability in various industrial settings. Particularly, their use in mining applications demonstrates their efficiency and robustness.

- In mining applications, these cylinders are utilized to handle heavy loads, ensuring safe and efficient operations. Their design is tailor-made to withstand the unique challenges of mining operations.

- Terrain adaptability is another significant feature of these cylinders. They can adapt to diverse terrains in mining environments, enabling controlled movements and facilitating operations even in varying terrain conditions.

- Finally, they support various attachments in mining equipment for effective material handling, thereby enhancing material transport capabilities and improving overall handling efficiency.

Frequently Asked Questions

How Do the Maintenance Requirements for Telescopic Cylinders Differ From Other Types of Hydraulic Cylinders?

In general, hydraulic cylinders require regular maintenance to increase their lifespan. This includes frequent seal replacements. However, the specifics of these needs can vary greatly depending on the type of cylinder used.

What Are the Potential Drawbacks or Limitations of Using Telescopic Cylinders in Machinery?

While they offer extended reach, telescopic cylinders may have load capacity limitations and slower retraction speeds. This could impact the efficiency and adaptability of machinery, particularly in heavy-duty industrial or construction environments.

Are There Specific Environmental or Climatic Conditions That Can Affect the Performance of Telescopic Cylinders?

Yes, certain environmental conditions can impact cylinder durability. Extreme temperatures, moisture, and corrosive elements can pose installation challenges and affect performance. Regular maintenance helps to combat these potential issues.

How Does the Cost of Implementing and Operating Telescopic Cylinders Compare to Other Hydraulic Solutions?

When considering cost, telescopic cylinder innovations and cylinder material selection can impact expense. They're often pricier than standard hydraulics, but their compact size and extended reach can justify the additional cost in many applications.

Are There Industry-Specific Telescopic Cylinders Available That Are Designed for Particular Applications or Sectors?

Yes, industry-specific telescopic cylinders do exist. They're designed for unique applications or sectors, featuring innovations in cylinder material selection to meet specific operational demands and environmental conditions.

Conclusion

To summarize, telescopic cylinders display a range of benefits in different industries, with their compactness, load handling, and adaptability standing out.

They're vital in machinery like dump trucks and cranes, and in aerospace and marine applications, they offer weight reduction and corrosion resistance.

Their extensive reach and precision control boost efficiency and safety. Understanding their features and benefits can help optimize their use, reinforcing their pivotal role in industrial machinery and technology.

1 thought on “Telescopic Cylinders”