Navigating the world of dump trailers is like sailing a ship through stormy seas; one must be well-equipped to handle the common problems they throw up.

From hydraulic system faults, structural and mechanical issues, to electrical problems, each can pose a significant challenge, but there's no need to raise the white flag just yet. This discussion will dissect these problems, revealing their causes and providing practical solutions.

As this unfolds, the importance of correct loading and unloading techniques will come to light. But why stop there? Let's take one step further and explore how regular maintenance can keep these problems at bay.

Key Takeaways

- Address hydraulic system issues by inspecting for leaks, checking fluid levels, and assessing pump functionality.

- Fix electrical problems by inspecting wiring, fuses, bulbs, and ensuring proper battery maintenance.

- Mitigate structural and mechanical issues through regular inspection and replacement of damaged components like tires and suspension parts.

- Prevent improper loading and unloading incidents by distributing weight evenly, staying within weight capacity, and unloading on level ground.

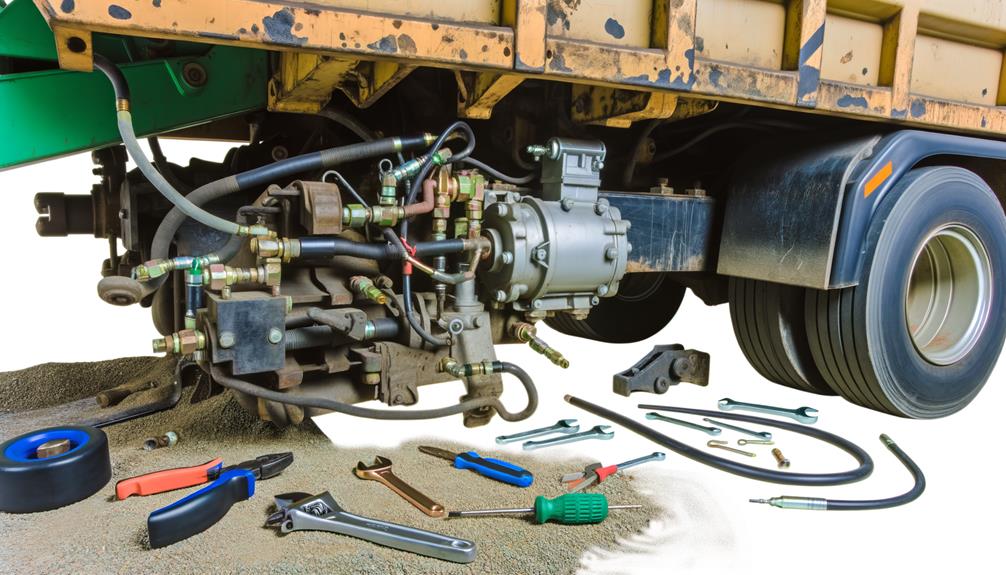

Addressing Hydraulic System Issues

A significant number of dump trailer issues stem from problems with the hydraulic system, ranging from leaking fluid to the trailer's inability to lift. Hydraulic fluid leaks, which can severely compromise the system's effectiveness, often originate from damaged lines, fittings, or seals. Diligent troubleshooting can identify these flaws, allowing for timely replacement and refilling of hydraulic fluid.

Similarly, a trailer's inability to lift or slow lifting speed may indicate a need for pump replacement. Troubleshooting the pump involves checking fluid levels and, if necessary, bleeding the system. If these steps don't improve functionality, pump replacement is likely required.

Solving Electrical Problems

Moving beyond the hydraulic system, another common source of dump trailer troubles lies within the electrical system. These issues often manifest as malfunctioning lights or electrical wiring complications. Troubleshooting lights is a common necessity. One must first inspect the bulbs and fuses, replacing any that are blown. Next, check the wiring for any visible damage and repair as necessary. Also, make sure the ground connection is secure. This checks off the main culprits of lighting issues.

Now, onto electrical wiring issues: these may affect not just lighting, but braking and battery function as well. A thorough inspection of the wiring, especially at connection points, will often reveal the issue. Repair or replace damaged wires to restore functionality.

Fixing Structural and Mechanical Issues

Beyond the domain of hydraulic and electrical issues, your dump trailer's structural integrity and mechanical components can also encounter problems that require prompt attention and repair.

- Frame Repair Techniques: Regularly inspect the frame for any signs of stress, cracks, or damage. If detected, consult with a professional for repair or replacement.

- Preventative Maintenance: Regular maintenance not only prolongs the trailer's life but also prevents major breakdowns. Keep a maintenance schedule.

- Tire Care: Check tire pressure regularly and look for tread wear or sidewall damage. Replace if necessary.

- Suspension Upgrades: Loose or damaged suspension components affect the trailer's performance. Inspect for wear, loose bolts, worn bushings, or bent parts and replace as needed.

Correcting Improper Loading and Unloading

While attending to structural and mechanical issues is key, it's equally important to correct any improper loading and unloading techniques that may contribute to dump trailer problems. Preventing tipping is a primary concern. This can be achieved by making sure a balanced weight distribution. It's essential to evenly spread the load across the trailer's bed, with more weight towards the front.

During unloading, operators should make sure the trailer is on level ground. An inclined or uneven surface increases the risk of tipping over. Next, the load should be discharged slowly, starting from the front, moving towards the rear. This method maintains the trailer's balance, reducing strain on the hydraulic system. By applying these practices, operators can significantly enhance the safety and longevity of their dump trailers.

Implementing Regular Maintenance Tips

To keep your dump trailer running efficiently and prevent costly repairs, it's crucial to implement a regular maintenance routine. A complete maintenance schedule includes several preventative measures designed to identify and address potential issues before they escalate.

- Frequent inspections: Regularly examine your trailer's structure, hydraulic system, and electrical components to identify any signs of wear, damage, or malfunction.

- Timely repairs: Promptly fix identified issues to prevent further damage and maintain peak trailer performance.

- Proper loading and unloading: Always distribute weight evenly and stay within the trailer's maximum capacity to avoid structural damage and maintain safety.

- Regular cleaning: Regularly clean your trailer to prevent corrosion and extend its lifespan. By adhering to these maintenance tips, you'll guarantee a long, productive life for your dump trailer.

Frequently Asked Questions

What Are the Common Factors Causing Corrosion in Dump Trailers and How Can They Be Prevented?

Corrosion in dump trailers often results from exposure to harsh elements and lack of maintenance. Regular use of corrosion detection techniques and applying anti-rust coatings effectively prevents this problem. It's important to maintain these practices.

How Can One Identify and Repair Issues With the Dump Trailer's Hitch System?

To troubleshoot hitch failures, they'll inspect the hitch system for wear, damage, or loose connections. Regular hitch system maintenance, including tightening bolts and replacing worn parts, will fix most hitch-related problems with dump trailers.

How Often Does the Hydraulic System of a Dump Trailer Need Professional Servicing?

While it varies, they typically recommend professional servicing of a dump trailer's hydraulic system annually. Regular maintenance, including hydraulic fluid replacement and addressing system overheating, can extend this timeline. It's best to consult your manual for specifics.

What Are Some Ways to Increase the Lifespan of a Dump Trailer's Battery?

To increase a dump trailer's battery lifespan, one should consider proper winterization and solar charging. Winterization prevents damage from freezing temperatures, while solar charging maintains the battery's power level, reducing strain and extending its life.

What Are Some Signs of Axle Misalignment in a Dump Trailer and How Can It Be Corrected?

Unusual tire wear patterns often indicate axle misalignment in dump trailers. Through axle replacement techniques, it's corrected. They'll first measure alignment, adjust if minor, or replace the axle if severely misaligned, ensuring smooth operation.

Conclusion

To sum up, operating a dump trailer efficiently is achievable by understanding common problems and their solutions.

From hydraulic and electrical issues to structural and mechanical faults, being knowledgeable is essential.

Correct loading and unloading techniques also play a key role in preventing accidents and damage.

Regular maintenance can't be overlooked as it guarantees top performance.

Armed with this guide, you're well-equipped to tackle any dump trailer issue that comes your way.