In the relentless world of heavy-duty machinery, isn't it often the unseen parts that cause the most trouble?

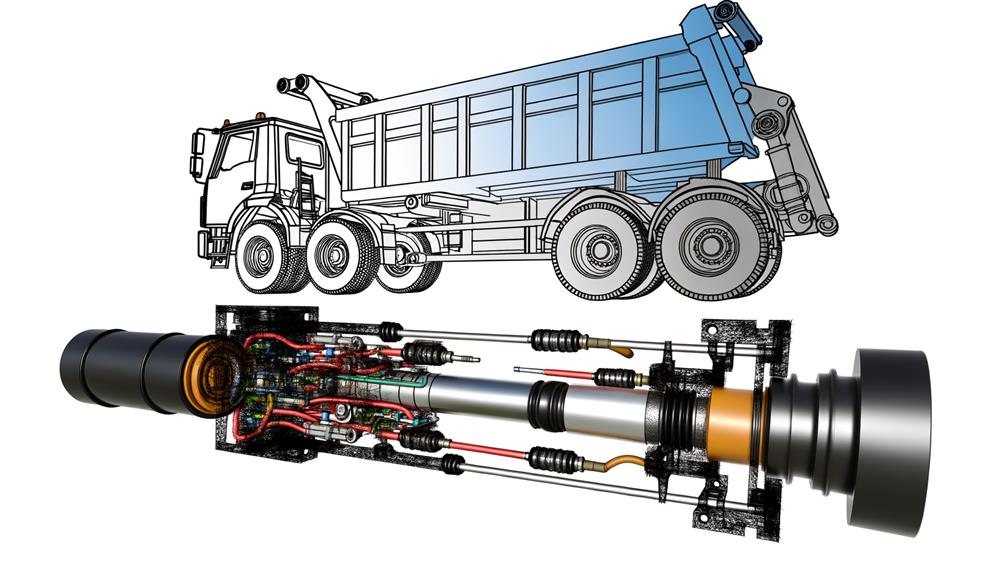

Dump trailer telescopic cylinders, while crucial for efficient operation, can present a series of challenges such as slow lifts, vibrations, or hydraulic fluid leakages.

This discussion aims to unravel the complexities behind these common issues, shedding light on the potential causes and practical solutions. Moreover, it seeks to provide a detailed guide on maintaining these cylinders effectively and knowing when professional intervention becomes necessary.

The path to improved productivity and reduced downtime begins here.

Key Takeaways

- Dump trailer cylinder issues often involve vibration, slow lifting, leakage, and functional problems with the tipper body and telescopic cylinder.

- Regular maintenance, including checking for obstructions, fluid levels, and system pressure, can prevent many common cylinder problems.

- Repair services specializing in telescopic cylinders can provide expert help in troubleshooting and fixing hydraulic issues in dump trailers.

- Additional resources provide valuable information on the costs and best practices for hydraulic cylinder repair and maintenance.

Dump Trailer Cylinder Operation Issues

Dump trailer cylinders can experience a variety of operational issues, such as vibration and chattering, immobility of the tipper body, slow lifting, hydraulic fluid leakage, and incomplete retraction, each requiring a unique set of troubleshooting steps.

When addressing vibration and chatter, checking cylinder alignment and troubleshooting potential friction issues is key. Also, ensuring proper hydraulic fluid management can prevent the immobility of the tipper body and slow lifting.

Issues with hydraulic fluid leakage often point towards a need to inspect the system's connections and hoses. Finally, incomplete retraction may indicate internal component damage. It's important to verify fluid levels, make sure no air is trapped, and seek professional maintenance if problems persist.

These solutions liberate operators from operational inefficiencies.

Telescopic Cylinder Maintenance

In maintaining the smooth operation of telescopic cylinders, it's essential to regularly inspect and address potential issues such as mis-staging and hydraulic problems. Preventive maintenance can include checking for air in the cylinder, verifying pressure ratings, and inspecting the cylinder stage sleeve for straightness. Should problems persist, a cylinder replacement might be necessary.

Troubleshooting tips for a malfunctioning cylinder also involve ensuring the machine isn't operating over the recommended RPM. It's critical that the system pressure rate aligns with the manufacturer's specifications. If the reservoir air breather is blocked, this can lead to significant issues. Hence, verifying that all hydraulic components are functioning optimally is a fundamental aspect of telescopic cylinder maintenance.

Dump Truck Hydraulic Issue

While maintaining telescopic cylinders often revolves around understanding and rectifying mis-staging issues, dealing with hydraulic problems in dump trucks presents its own unique set of challenges.

The key to hydraulic system troubleshooting lies in meticulous inspection of each component, from the reservoir air breather to the cylinder stage sleeve. Any obstruction under the body can lead to considerable issues, and a straight cylinder stage sleeve is paramount for smooth operation. System pressure rates need careful monitoring and verification, ensuring that the hydraulic components are functioning as they should.

When issues persist, professional telescopic cylinder repair becomes important. Despite the potentially high cost estimation, this could prevent further damage and considering the longevity of the dump truck's hydraulic system.

Repair and Maintenance Recommendations

To keep your dump trailer's hydraulic system in peak condition, it's important to regularly troubleshoot any ongoing issues, engage professional help for maintenance, and guarantee the quality of the hydraulic cylinder repairs.

Hydraulic system troubleshooting can be challenging. Hence, understanding common cylinder problems and repair techniques is key. Maintenance tips include regular fluid checks, air bleeding, and component inspections. If issues persist, professional help should be sought.

One shouldn't skimp on quality when it comes to hydraulic cylinder repairs. Poor repairs can lead to further damage and even system failure. Hence, it's essential to make sure any repairs are done by skilled technicians using appropriate tools and techniques.

Dump Trailer Cylinder Repair Services

After guaranteeing quality repairs and maintenance, it's equally important to engage the services of experts specializing in dump trailer cylinder repairs. These professionals have the knowledge and skills to perform hydraulic system troubleshooting, ensuring peak performance and longevity of your equipment.

- Inspection and Diagnosis: Experts thoroughly examine your system, identifying potential problems. They use advanced cylinder repair techniques to pinpoint issues and offer solutions.

- Repair and Replacement: Depending on the diagnosis, specialists may repair or replace defective parts. They ensure that all components are functioning properly, reducing future breakdowns.

- Maintenance and Advice: Beyond repair services, experts also provide maintenance tips to prevent issues. They offer advice on maintaining hydraulic systems, empowering owners with knowledge for freedom from frequent breakdowns.

Frequently Asked Questions

What Are the Safety Precautions to Take When Troubleshooting Dump Trailer Telescopic Cylinder Problems?

When troubleshooting dump trailer telescopic cylinders, one must wear personal protective equipment, know emergency procedures, and maintain a safe distance from the machinery. It's essential to shut off power before inspection to prevent accidents.

How Often Should Routine Maintenance Be Performed on a Dump Trailer's Hydraulic System?

They should perform routine maintenance on a dump trailer's hydraulic system every six months. This includes hydraulic fluid changes and cylinder seal replacements, ensuring the system's efficient and prolonged operation.

What Are the Signs That a Dump Trailer's Hydraulic Cylinder Is Reaching the End of Its Lifespan?

Signs a dump trailer's hydraulic cylinder's nearing its end include frequent cylinder leakages and excessive replacement costs. It's important to monitor for these indicators to avoid major operational issues or complete system failure.

Are There Any Specific Brands or Types of Hydraulic Cylinders That Are More Reliable for Use in Dump Trailers?

He's found that brands using high-grade materials provide more reliable cylinders. Durability of the cylinder material and the type of hydraulic oil used greatly influence their performance and longevity in dump trailers.

How Can Weather Conditions or Environmental Factors Impact the Performance and Longevity of a Dump Trailer's Telescopic Cylinder?

Extreme weather and environmental factors can degrade a dump trailer's telescopic cylinder, causing performance issues and reduced lifespan. Cylinder corrosion prevention and understanding seasonal performance variations are keys to maintaining hydraulic equipment's durability and efficiency.

Conclusion

In conclusion, addressing common dump trailer telescopic cylinder problems promptly and effectively is important in maintaining top functionality. By understanding the causes and implementing the solutions to issues such as vibrations, slow lifts, and hydraulic fluid leakages, operators can greatly boost productivity and reduce downtime.

Regular maintenance, coupled with professional repair services when necessary, guarantees the longevity of these heavy-duty machines. Hence, effective troubleshooting and maintenance practices are paramount in the world of dump truck hydraulics.